FAQs

Search FAQs

Cantilever

Find out more about the uses and benefits of cantilever racking.

Find out more about the uses and benefits of cantilever racking.

Find out more about the uses and benefits of cantilever racking.

View our cantilever racking solutions.

Read our blog post ‘What is cantilever racking?’.

Inspections

Our inspector will then walk the site thoroughly investigating the racking and making note of any damage and general housekeeping. Before leaving site, the inspector will make the PRRS aware of any concerns that need to be addressed ASAP and will ensure they are complete before leaving.

Once the inspection is complete, our inspector will complete the report and send to the Person Responsible for Rack Safety within 1-2 days.

Find out more about our racking inspections.

Please do give us a call and we can discuss your options with you.

Contact us for more information.

Any damage that occurs should be identified when it occurs, the rack unloaded, and the damage remedied.

Find out more about our racking inspections.

Though the term “recommendation” may not seem as strong a term as “requirement,” don’t let that fool you into thinking you’re less at risk if you’re found not to follow them.

If someone is injured due to poor racking safety, a claimant could prove that the warehouse didn’t follow HSE recommendations and, if convinced, you could be held legally responsible. These recommendations have to be followed to a degree that’s considered “reasonably practicable”.

Find out more about our warehouse racking inspections.

Taken from ‘Warehousing and storage, A guide to health and safety’ produced by HSE ‘to ensure that a racking installation continues to be serviceable and safe, the storage equipment should be inspected on a regular basis.

The frequency of inspections depends on a variety of factors that are particular to the site concerned and should be determined by a nominated PRRS (Person Responsible for Racking Safety) to suit the operating conditions of the warehouse. This will take into account the frequency and method of operation together with the dimensions of the warehouse, the equipment used and personnel involved, all of which could damage the structure.

Find out more about why you need a SEMA racking inspection.

Mezzanine

Outdoors

Utilising outdoor space can be a great way to increase the amount of storage capacity you have. It can also give customers direct access to products they can pick themselves.

A typical racking system for outdoor use is cantilever racking.

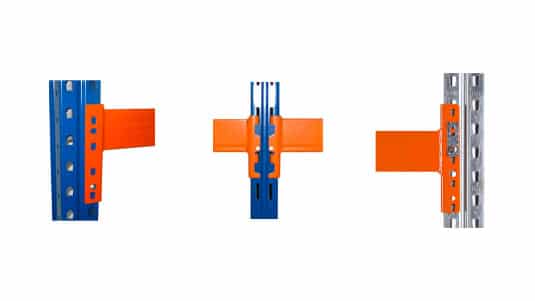

Pallet Racking

To maintain adjustable pallet racking, you should regularly inspect the racking for any signs of damage, such as bent or broken beams or loose connections. Make sure that pallets are properly loaded and that the weight is distributed evenly. Keep the area around the racking clean and clear of debris. Train your employees on proper racking safety procedures, and also arrange a SEMA racking inspection regularly.

There are several types of pallet racking you can get, including adjustable pallet racking, drive-in/drive-through racking, push-back racking, and cantilever racking. Each type is designed for specific storage needs and can be used in varying warehouse layouts.

Racking

We have a brand-new system called Gondola Skate. Our innovative product can mobilise and move shelving units of any type in 20 minutes, without the need to de-merchandise or empty shelves of stock.

Take a look at our video to see it in action.

Find out more about our warehouse racking mobilisation.

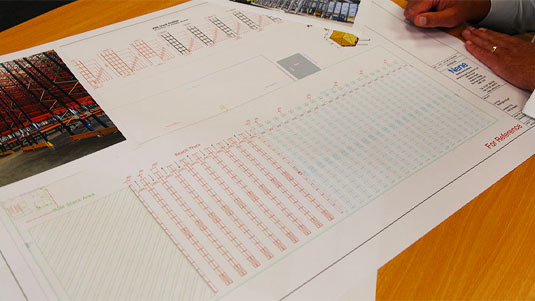

This gives us the opportunity to get a good look at the site and discuss all your business needs so we can design the right solution for you.

They are common in warehouses as they make great use of unused vertical space. They provide high quality, extremely cost-effective additional space in areas that are often never used, with handrail and gate systems also available.

Find out more about mezzanine floors.

Warehouses are busy places and putting safety products such as Rack Deflektors and End of Rack Barriers in place will make a big impact in reducing damage.

Our experts are best placed to advise on ways to prevent damage reoccurring. Contact us today for a free, no-obligation site survey.

View our range of warehouse racking protection.

The aperture in the decking allows sprinkler systems to work more efficiently in the event of a fire over standard conventional solid timber decking. They are super easy and quick to install, dropping in to place with absolutely no fixings.

We have over 40,000 mesh decks in stock in locations across the UK and Europe, allowing for short lead times on standard sizes. We also offer custom sizes available to order.

Find out more about our wire mesh decking.

We have worked with every industry you can imagine, and they all have special and unique requirements.

Take a look at our case studies for some examples of what we are capable of..

It is a flexible and versatile way of getting the racking you need for your business. Hire periods run for anything from four week to five years.

Design install and ongoing racking maintenance are all included in the monthly cost making it a fantastic all-inclusive option.

Find out more about our racking hire.

This gives us the opportunity to get a good look at the site and discuss all your business needs so we can design the right solution for you.

Just take a quick look at our what racking do I have? page to identify your racking system.

If you are still stuck please do give us a call.

With over 40 years’ experience, dedicated project managers, and a huge centrally located stock holding we are true experts in our field and can guide you through every step of the process to get the right storage solution for you.

We are SEMA accredited and put safety at the forefront of all we do.

Contact us today for a free site visit to discuss your needs.

This ensures that your installation is both safe and compliant.

Here at Nene we put safety at the forefront of all that we do and only provide the best SEMA approved racking installs.

Find out more about our SEMA accredited racking installations.

With over 40-years’ experience, we can help you determine the best system for you and guide you through every step of the process.

We offer a free no-obligation site visit where one of our team will come to you, complete a full site survey and chat through your requirements.

We have worked in a wide variety of sectors and will be able to help you make the best choices for your business.

Contact us for more information.

It will allow you to hugely increase your storage capacity as well as store your products in a more organised and efficient manner, improving both picking times and profitability.

It can also speed up stock takes and help to reduce the number of products that get damaged while in storage.

Find out more about our warehouse racking systems.

Safety

They should have received training so they can fulfil this role safely and in line with all relevant regulations.

If you would like to become a PRRS for your business, please visit our Racking Awareness Training page to find out more.

See our blog on frequently asked questions by PRRS.

Have a question?

Let us know if you have any questions and our friendly experts will contact your with more information.