Warehouse Automation

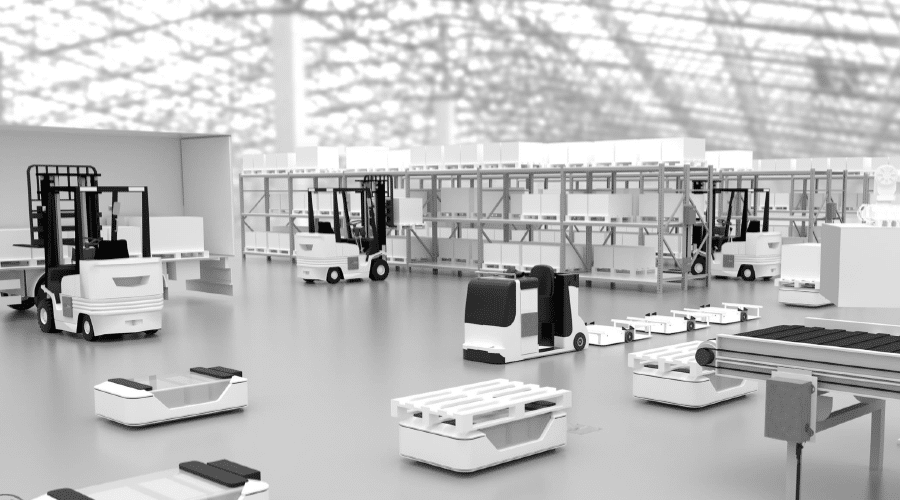

We provide cutting-edge automated warehouse system for automating your warehouse and improving your productivity.

Offering AI technology, cloud software and innovative engineering to streamline and modernise warehouse operations whilst ensuring continuous ROI. With a need for maximum performance and efficiency, advanced automation solutions help reduce costs, improve accuracy and provide scalable opportunities. With 25 years of warehouse robotics experience, we recommend the best automated system to suit and enhance your setup.

Warehouse Automation Solutions Range

1D Warehouse Shuttle System

This innovative system employs automated shuttles that move horizontally within a racking structure, providing fast and efficient storage and retrieval of goods. The 1D pallet shuttle system can handle different types of loads, including pallets, boxes, and trays.

2D Warehouse Shuttle System

The 2D Pallet Shuttle System is a cutting-edge solution that utilises automated shuttles capable of both horizontal movement in two directions within a racking structure. By combining high-speed performance and remarkable precision, this innovative system optimises storage density and significantly boosts productivity.

e.scala Robots

e.scala robots provide a seamless automated fulfilment system for industries focused on good-to-customer orders. The scalable ramp racking system allows the e.scala bot to quickly manoeuvre in 3 dimensions, up to 50m2, to increase productivity times and order precision.

Autonomous Mobile Robots (AMRs)

Enhance your workforce with Autonomous Mobile Robots. Built with the latest AI technology, object recognition and safety sensors, they have the flexibility and full capabilities to complete operational tasks on your warehouse floor. Often providing a safer solution for tasks which could be harmful to humans, and therefore creating a safer, more productive environment.

Autonomous Case-Handling Robots (ACRs)

Installing an automated case-handling system for picking and packing businesses can extensively increase storage space and productivity. Optimising aerial space, these multiple-racking systems only require a few weeks to install and use lifts and mapping navigation to manoeuvre, pick and collect real-time orders.

The Benefits Of Warehouse Automation

Warehouse Automation offers numerous benefits that enhance the efficiency and productivity of warehouse operations. Here are some key advantages of using Nene Warehouse Solutions Warehouse Automated Solutions.

1. Increased Productivity

Warehouse Automation systems can handle high volumes of goods with minimal labour requirements, allowing for faster and more efficient processing of orders and reducing the time required for inventory management.

2. Improved Accuracy

Automated warehouse systems reduces the risk of errors and improves accuracy, leading to fewer returns and higher customer satisfaction.

3. Enhanced Safety

Warehouse automation solutions are designed with safety in mind, featuring advanced sensors and safety features to protect employees and goods from harm.

Warehouse Automation Resources

Browse our expert guides to find out all you need to know about Warehouse Automation.

The advantages of Picking Systems

Find out how the The 2D Shuttle System can help your warehouse.

Get in touch with the Nene Warehouse Solutions Team

Speak to our warehouse automation experts to discuss your project, simply fill in the form below.

A complete solution

We offer a wide range of complementary products, accessories and services. Our friendly team of expert advisors is on hand to help with any questions you have about your specific requirements and can visit your site to help you determine your exact requirements.