Racking Inspection Training

Are you responsible for maintaining the safety and efficiency of your warehouse operations? Ensure your racking systems are up to industry standards with our comprehensive Racking Inspection Training courses, carried out by our SEMA Affiliated Approved Racking Inspectors.

Why choose our racking inspection training?

Nene’s racking inspection training comprises full-day courses that provide you with extensive training, giving you the knowledge and the confidence to carry out thorough racking inspections. Learn more about what sets our training apart below.

Delivered by SEMA Approved Rack Inspectors

Learn from certified professionals with years of industry experience.

Comprehensive Curriculum

Covering all aspects of racking inspection, including safety regulations, and practical inspection techniques.

Hands-On Experience

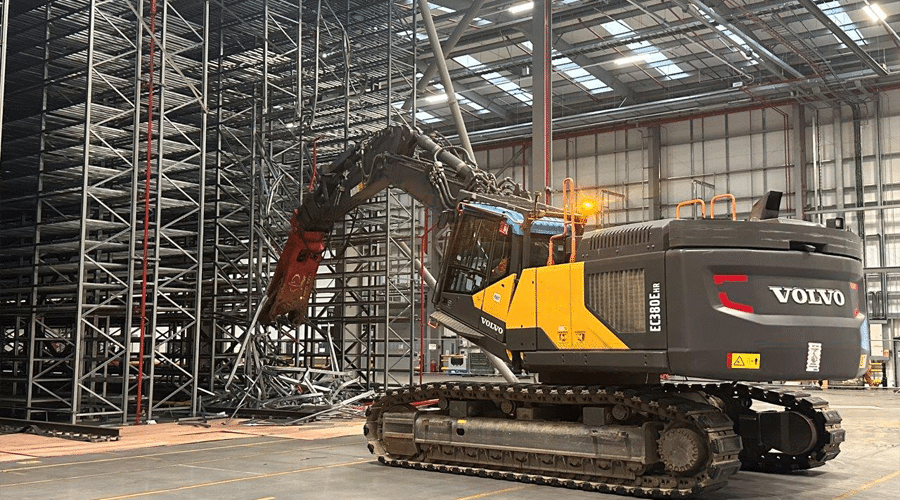

Practical training sessions in a real warehouse environment to ensure you’re fully prepared for on-the-job challenges.

Ongoing Support

Access to our experts for advice and guidance even after your course is complete.

I’ve been working in warehouse management for over a decade, and I can confidently say that Nene’s Racking Inspection Training was a game-changer for me. The course is meticulously designed to cover every aspect of racking inspection, from understanding the latest safety regulations to practical, hands-on training.

The instructors are industry veterans who bring a wealth of experience and knowledge, making complex concepts easy to understand. I appreciated the focus on real-world application; we didn’t just sit in a classroom all day—we got to work in a live warehouse environment, inspecting actual racking systems and learning how to spot potential issues.

The training has not only equipped me with the skills to conduct thorough inspections but also given me the confidence to ensure that our warehouse operations meet the highest safety standards. The skills and knowledge I gained have already proven valuable in my role, allowing me to implement changes that have significantly reduced our risk of racking-related incidents. I highly recommend this training to anyone serious about warehouse safety.

John

Warehouse Manager

Upcoming Training Events

Don’t miss out on our upcoming training sessions, designed to fit your schedule. Our full-day courses provide extensive training, ensuring you leave with the confidence and knowledge needed to carry out thorough racking inspections.

Racking Inspection Training Event

- Full Day Training: Covering theoretical and practical aspects of racking inspection.

- Location: Sessions available at our Midlands Head Office, ensuring convenience for all participants.

- Dates: The last Thursday of each month

Ready to Enhance Your Skills?

Invest in your career and workplace safety by enrolling in our Racking Inspection Training today. For more information or to book your place, contact us below

Course Curriculum Overview

Our Racking Inspection Training course includes:

-

Understanding the importance of regular inspections.

-

Identifying potential hazards in racking systems.

-

Hands-on training on inspecting various racking systems.

-

Overview of SEMA guidelines and industry standards.

-

Implementing safety measures to minimize risks.

-

Recognizing signs of wear, damage, and structural issues.

Please note: This course does not provide a SEMA qualification; however, participants will be trained to conduct an intermediate safety inspection following the SEMA and HSE Guidelines. The course is demonstrated and conducted at ground level only.

Cancellations: We require a minimum of 5 working days for any cancellations.