How Nene Utilises Technology To Manage Racking Inspections

Contents

Racking inspections are essential for safe and secure working warehouse environments. With SEMA racking inspections required annually as a minimum, the process ensures that everyone working in and around the racking is safe and protected, the equipment is productive, and, as a result, falls in line with industry regulations (making that all-important insurance valid).

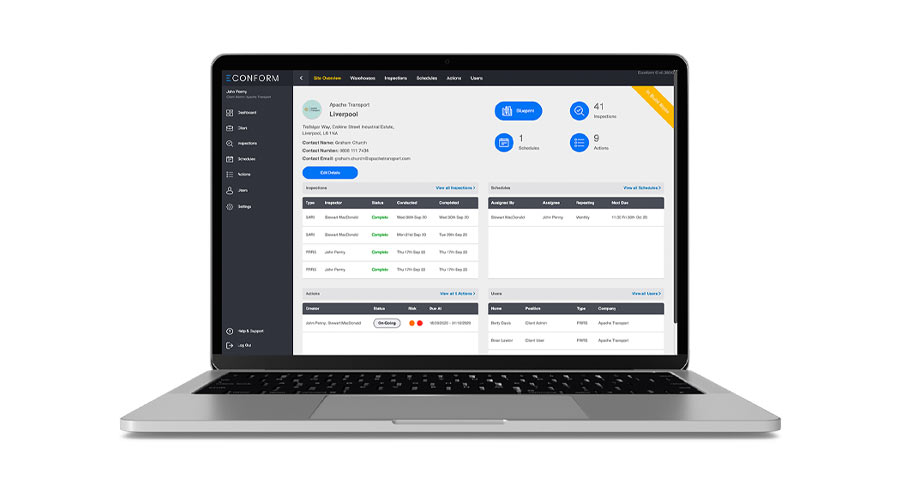

To do this, we look to technology and innovation, which helps us to provide more slick, smart and intelligent services for our clients. Our SEMA accredited racking inspectors use a cloud-based digital platform, Econform, to ensure premium warehouse safety measures and reporting are front and centre for clients and their employees.

How Technology Improves Racking Inspections

So how does it work?

The naked eye will always be critical for inspection, so AI isn’t taking over here. What technology does, however, is provide support for inspectors through ease of use, real-time access to rich and accurate inspection data, multi-user access from anywhere, and high-quality reporting – all contributing significantly to mitigating risk and standardising the approach to rack safety management. Being cloud-based allows for a complete multi-user experience, so information can be added, edited and drawn upon whenever and wherever clients need it. The app allows the software to be completely mobile, and it comes with desktop features for when you need to collate paperwork, file projects and sign-off information.

And it’s working – Econform has quickly gained recognition, winning multiple awards for innovation and business. But more than that, it is serving clients and protecting employees across the UK. .

Find out more about Econform’s racking management software.

Speed up the time between identifying damages to getting them repaired, therefore reducing downtime of your valuable storage space…

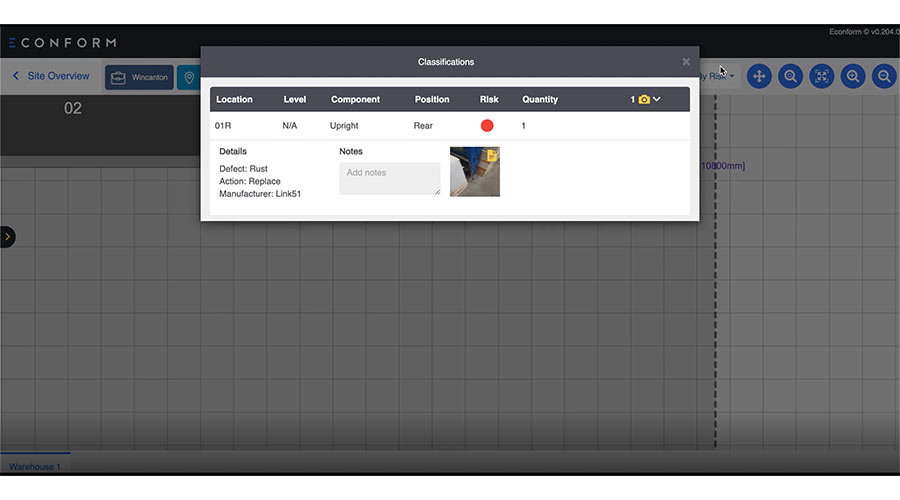

The Econform platform has been designed from the ground up with the knowledge and experiences of SARI’s, suppliers, manufacturers, clients and installers. By taking into consideration all links in the chain, the system removes the ‘interpretation’ sometimes required and supplies accurate information to ensure the right component is called off and installed.

Econform’s Racking Management Software

Racking Asset Management Tool

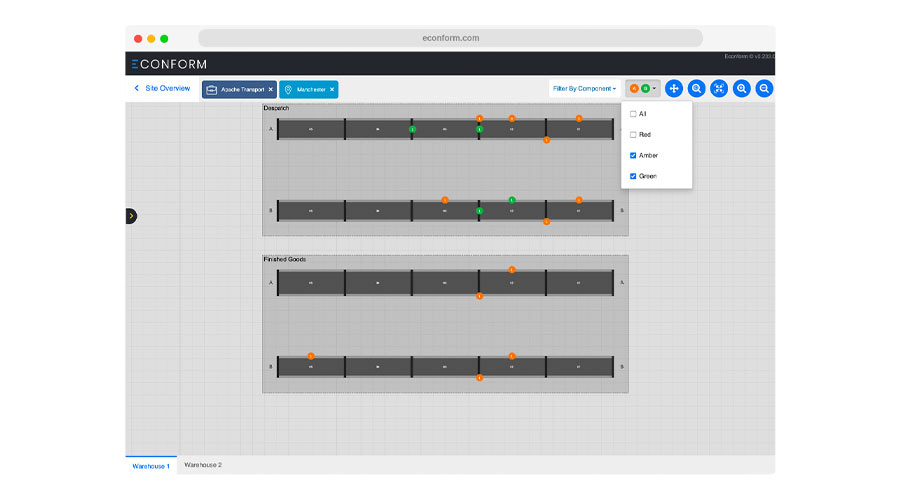

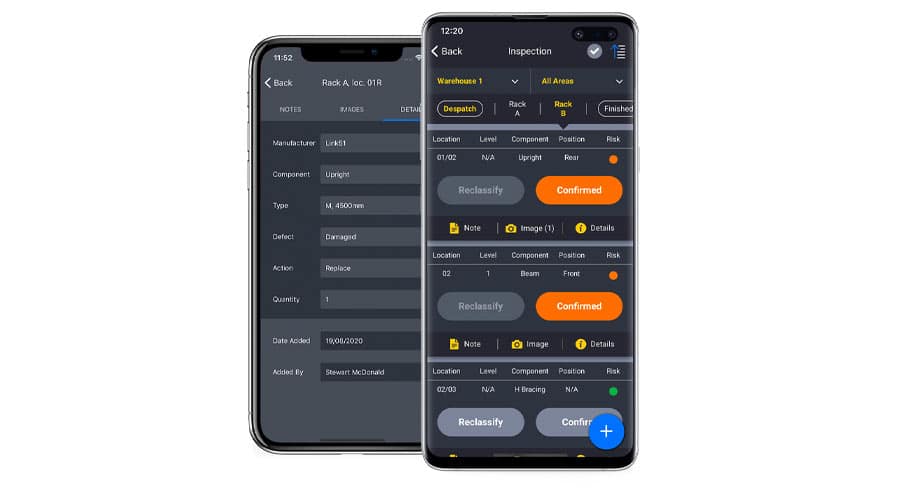

The Econform app is set up for clients by our Racking Inspection Team. Following an initial site survey, they input a digital map of your warehouse facility to the app, including all the racking components. Everything that is up for testing and inspection, from nuts, and bolts to joists and beams is collated, added and clearly marked for anyone to access on the interactive, in-app map. Set up in zones and with quick access to an area you want to review or edit, this information is the perfect asset management tool, monitoring and recording sizes, specifications and any other component details you require.

Racking Inspection Checklist

Using the app couldn’t be simpler. Our racking inspectors will use the same SEMA guidance and regulations you are used to, working through the comprehensive racking inspection checklist to look for signs of damage, twisting, wear and tear, missing items, overloading and other functional and safety issues. Using Econform, they record their findings into the software as they go on their device, using the traffic light system to flag issues, building up a real-time picture of the state of the racking. With its multi-UX capabilities through the app, internal teams and permitted stakeholders can access the information, monitor and log details and safety concerns, and generate reports.

Find out more about racking inspection checklists.

Racking Inspection Reports

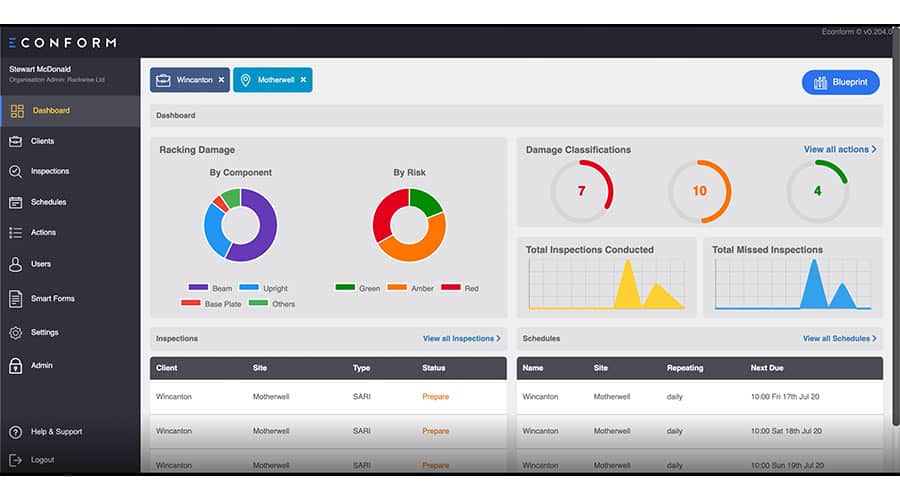

The critical information logged throughout the inspection is collated through an online dashboard on Econform. The initial report will show the findings from the traffic light classifications, from which the programme produces a second report with each racking component at fault flagged and all information provided, including sizes and specifications, ready for ordering and replacement.

Warehouse managers can log in at any time to view their site’s inspection reports, which Nene also use to order the replacement racking and repair the damaged components.

There is an obvious time benefit here, with instant access to reports and parts lists available, which naturally decreases productivity downtime and reduces time wasted in unnecessary communications. Access to the information you need at your fingertips.

Find out more about SEMA racking inspections.

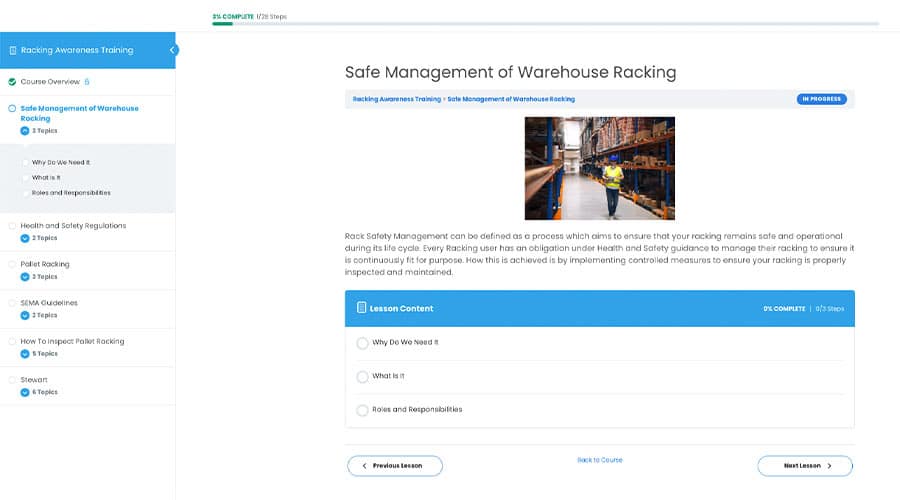

Online Racking Awareness Training

The Econform platform includes online Racking Awareness Training courses, enabling the Person Responsible for Rack Safety (PRRS) to keep up to date with the latest racking regulations and to understand how to properly maintain their racking safely. Using the platform to carry out their own in-house racking inspections allows the PRRS to ensure they can report damages when they occur, speeding up the repair and getting their racking operational again in the quickest time possible.

Find out more about Racking Awareness Training.

Web App

Through Econform we are able to directly source and collate information for our clients, but also empower them to understand, own and take responsibility for their inspection data too. The software is powered by a powerful desktop solution, driving all the assets and mobile app, providing clients with the ultimate user experience. Advanced technology means it’s easy to use, with mapping and set-up done by our teams with a full bespoke onboarding programme so clients can begin working with the data straight away. With 360° views of your warehouse and estate and everything filed from screws to complete storage systems, clients have everything they need for their specific operation.

Mobile App

We’ve talked already about the mobile app and with good reason – it’s the first of its kind in warehouse safety compliance. The app is powered by desktop software and syncs automatically, providing real-time data and analytics at the fingertips of our clients and inspectors. This crucial modernisation means that damage and wear and tear will not be left to deteriorate further due to time constraints or a breakdown in communication. With multiple users able to access the information anywhere at any time, safety is increased significantly and so too is client confidence – safe in the knowledge that nothing is left to chance. As ever, it’s simple to use, free, and downloadable from the Apple and Google Play Stores.

Nene Group and Econform

At Nene, we are proud innovators and believe that modernisation is critical to client satisfaction and in moving our industry forward. Our technology arm, Nene Tech Group recognises and celebrates the evolving markets and demands of our industry. By continually looking for new ways to improve the safety and well-being of everyone working in the sector, we can offer digital solutions such as Econform to help our clients to maintain a safe and healthy workspace.

Econform is our bespoke warehouse safety software, and our clients can fully digitise racking management through technology, resulting in the best quality reporting and online training resources available when they need them.

Our goal is to transform racking safety management with solutions that put clients in control of their environment.

Our mission to be the number one choice for clients is driven by our continued commitment and investment in technology and innovation. Econform will improve the racking inspection process, improving efficiency, productivity, compliance and safety for everyone involved in the warehouse industry.