O U R W O R K

Case Study: Removal of Automatic Storage and Retrieval System

Location: N/A Date of Project Completion: 15th December 2023 Warehouse Area: N/A Case Study Submitted by: Jerome McAllister

Overview

Nene Warehouse Solutions recently completed a challenging and innovative project involving the removal of an Automatic Storage & Retrieval System (ASRS) for a high-profile automotive manufacturer. This case study outlines the project requirements, the unique challenges faced, and the solutions implemented to ensure a successful outcome.

Project Requirements

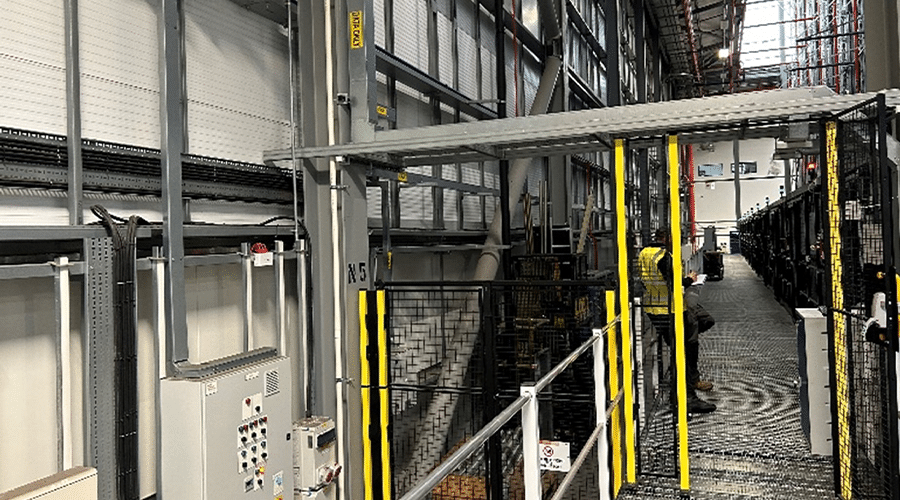

The client approached NWS with a specific need to dismantle and remove an ASRS that had become no longer in need for requirement. Despite the system’s relatively recent installation, advancements in technology meant that more cost-effective and flexible solutions were now available. The system comprised a complex selection of components including pedestal robot pallet decanting cells, extensive conveyor systems, miniload storage and Retrieval Machines (SRMs) standing over 20 metres tall, double deep tote racking with over 150,000 locations, in-rack sprinklers, pedestrian access gantries and critical electrical panels.

The Challenge

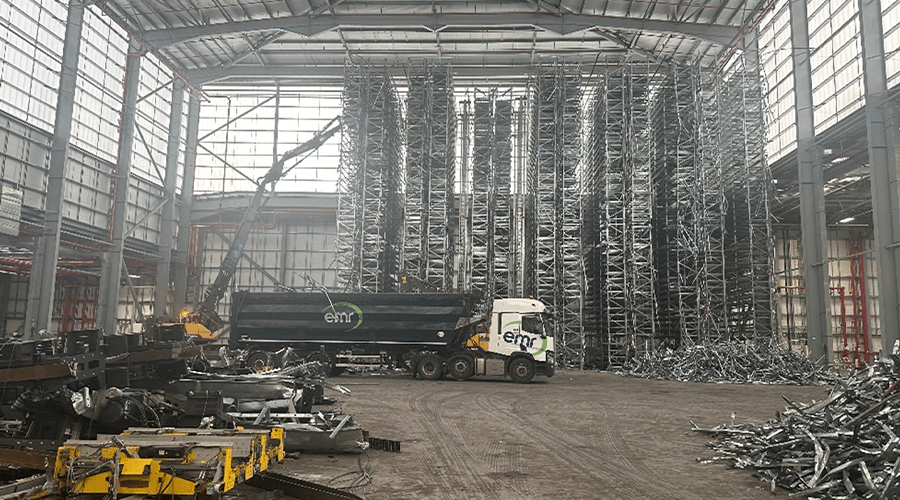

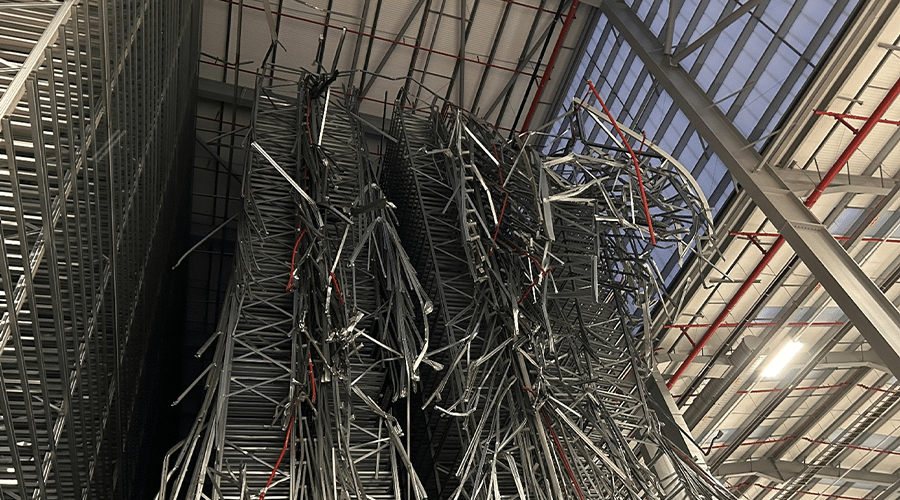

The main challenge in this project was the safe removal of the racking and SRMs. The bolted construction of the long bays of racking, exceeding 10 metres in height, presented a non-standard removal challenge. After a comprehensive review process, it was determined that demolition was the safest and most efficient method of removal, prioritising safety above all other considerations, including time and cost.

The Solution

NWS employed an innovative approach by using an armoured excavator for the demolition, avoiding the need for engineers to work at dangerous heights. The demolition phase was thoroughly planned and executed with NWS coordinating over 30 skilled fitters for the mechanical removal, supported by Nene Electrical for safe electrical isolation. This phase was completed in a remarkable time frame, with the entire strip-out completed in just one week and the demolition finishing three weeks later, a week ahead of schedule.

Impact and Benefits

The project was marked by several key achievements.

Safety

The use of an armoured excavator and careful planning ensured the project was completed without safety incidents.

Efficiency

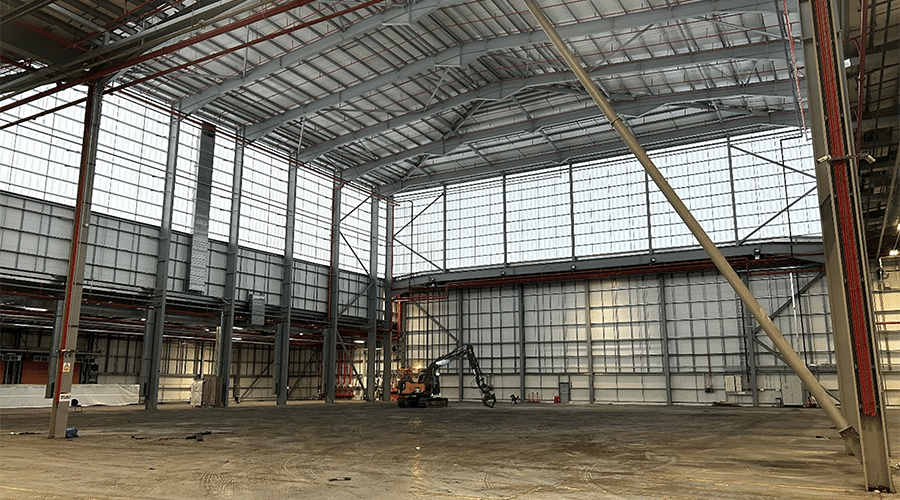

Completing the project ahead of schedule minimised disruption and allowed the client to proceed with their operational plans more quickly.

Innovation

Demonstrating NWS’s capability to tackle complex and unconventional project through innovative solutions.

The Conclusion

The project exemplifies Nene Warehouse Solutions’ commitment to delivering bespoke, safe, and efficient warehouse solutions. Our ability to adapt and innovate in response to unique challenges reinforces our position as a trusted partner in the warehouse and logistics sector.

To find out how Nene Warehouse Solutions can help improve your warehouse efficiency contact the team today, and speak to the warehousing experts.