5 Steps Towards a Greener Warehouse

Sustainability is now a mainstream talking point in most industries, and government legislation has escalated the climate conversation further. In November 2008, the climate Change Act passed in the UK parliament with an overwhelming majority across political parties. Initially, the Act set out plans for an 80% reduction in greenhouse gas emissions by 2050. In 2019, however the stakes were raised again when the UK became the first major economy to set a legally binding target to cut greenhouse gas emissions down to Net Zero by 2050.

The end goal is clear, but how business collectively contribute toward achieving such an ambitious target may not be as clear to some. It has to be said that: Industry does not have the best reputation concerning resource or climate preservation. Official statistics estimate that in 2018, the UK generated 43.9 million tonnes of commercial and industrial waste!

So what does eco-friendly look like within the Storage & Logistics sector? To help you make sense of a rapidly shifting landscape, we’ve outlined some of the fundamental concepts behind a Greener Warehouse below.

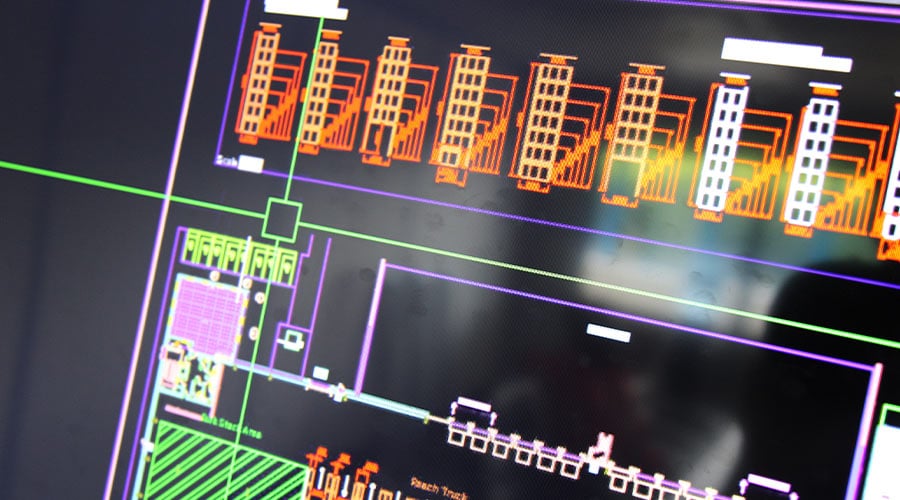

Warehouse Layout

The design of your warehouse is an crucial to your carbon footprint as it is to its success. A meticulous layout can boost productivity and efficiency by prioritising your primary units and accounting for product size, storage requirements, traffic flow, packing areas, and loading bays. Adequate floor planning will improve picking efficiency, reducing errors and the time it takes to fulfil orders – saving you labour and energy costs.

If looking to expand your operation, first evaluate the available headroom in your warehouse before exploring external options. Is your storage equipment optimising the space you have? High-density storage solutions such as Live Storage, Drive-In, and VNA (Very Narrow Aisle) or even automated shuttles can help. Racking can help you to maximise your warehouse potential.

Additionally, installing a Mezzanine Floor is a great way to increase capacity without affecting your floor plan. Free-standing and fully customisable, a single or multi-tiered mezzanine will give you additional storage or production areas at a fraction of the cost of extending your existing building or relocating.

Waste Management: Reduce, Reuse & Recycle

Okay, so no prizes will be handed out for this tip; we are all aware of the environmental harm caused by excess waste. But while waste management may be second nature at home, it’s surprising how many businesses still neglect their responsibilities.

The first step toward implementing a successful waste management scheme is to examine the waste you produce and consider if alternative solutions would reduce your waste output. Packaging, for example, is one of the worst contributors to waste in the warehouse environment – but there are alternatives to mummifying outbound products in tonnes of synthetic plastic!

Switching to biodegradable products and using less packaging will save you money and reduce your carbon footprint simultaneously. Reusing wooden pallets, cardboard boxes, and inbound packing will maximise your return on investment, ensuring you extend the lifespan of materials before they become waste.

And finally… if you’re not recycling – start now! The typical warehouse materials: paper, cardboard wood (in the form of pallets), steel, and even electrical waste, are all relatively easy to manage. Identify the recyclables within your warehouse, introduce the correct means of disposal, and ensure the measures are convenient and communicated clearly to your team.

Make Every Drop Count!

Water conservation will likely be one of the biggest environmental challenges we face this century. It’s predicted that climate breakdown will exacerbate an already depleting water supply over the next 25-30 years.

The water used in warehouses through manufacturing, cold storage and transporting of products, for example (not to mention warehouse sanitation facilities such as restrooms and washrooms), far outweighs the water consumption of the average UK household. Luckily, there are solutions available that can help you mitigate water waste in the workplace.

Installing low-flow plumbing fixtures to all your water dispensers and toilets is an easy place to start. Flow Restrictors and Aerators can reduce water usage by as much as 50% – and while implementation requires an upfront investment, such a waste reduction will undoubtedly lower your overall operating expenses.

If you have inherited an old facility with outdated apparatus, losing water can threaten your environmental efforts and your employees’ health and safety. Adopting a vigilant approach to your plumbing system is a healthy practice. Regular inspections of pipework and facilities – checking for leaks, rust, and cracks – and addressing issues without delay will limit water loss

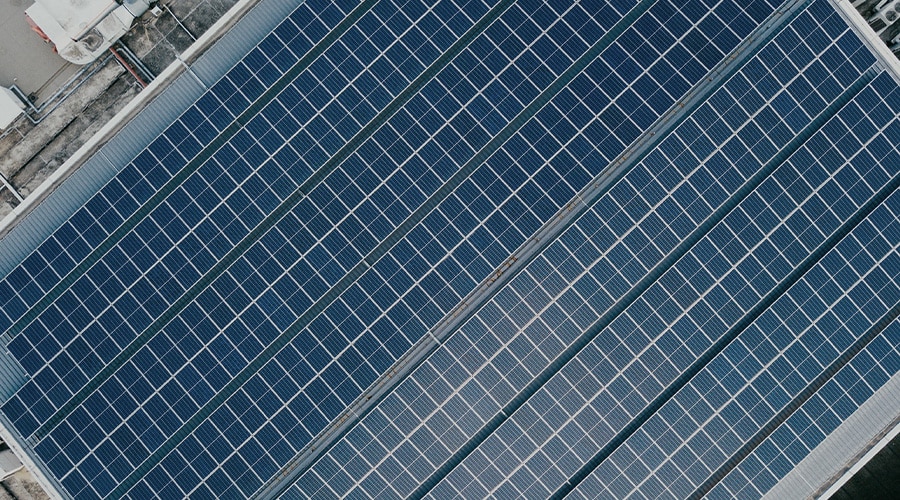

Green Lights

There’s a dizzying array of options to consider when lighting your warehouse, but LED lighting is a no-brainer when seeking sustainability. They’re not just demonstrably more energy efficient than their fluorescent and incandescent counterparts; but also brighter, more durable and free of toxic chemicals.

Investing in eco-friendly LED’s can reduce your energy consumption by up to 75%! Not to mention that bolder, longer-lasting light means fewer bulbs and less maintenance – providing both short and long-term savings. Motion sensors and Smart LED systems are also well worth your consideration, especially down racking aisles and areas of your building that see limited activity or varying shift patterns.

And let’s not forget – the Sun! Where possible, utilising natural light in your warehouse through thermal or double-glazed windows and skylights can further reduce energy consumption. Plus, the natural light is good for your mental health!

Go Electric!

An encouraging shift toward electric forklifts and counterbalance trucks occurred in recent years. As found in the automotive industry, it’s not been an easy sell convincing people to switch from the popular diesel and LPG fuelled trucks. But improvements in performance and efficiency, combined with rising fuel costs, have been hard to ignore.

Electric trucks are now just as capable as fuel-powered trucks; newer models can support loads of up to 8,000kgs and handle a wide range of materials. Smaller turning circles, advanced breaking systems, and operator-friendly controls show that the future of mechanical handling is fully invested in electric power.

Fewer moving parts make them a low-maintenance option too. Durable components, longer service intervals, and none of the fluid waste or pollutants (usually associated with gas and diesel-powered trucks) make the switch to a zero-emission fleet a wise long-term investment.

Speak To The Experts

If environmental policy is a new concept for your business, applying some of the strategies above will certainly get the ball rolling – instilling a lasting culture within your team will be the difference-maker, however, being eco-friendly is a continual process and one that takes root slowly, Try to avoid chastising employees or any forceful impositions. With thorough preparation and the appropriate measures established, positive change will come through transparent leadership and a non-judgemental working environment.

Turing the ship around will be no easy feat, but that’s not to say that everything is doomed! Carbon-neutral warehouses have already begun to spring up across the globe, and those in the positions to affect change are beginning to see the light by dint of the secondary benefits of going green, in addition to impact on climate change. As outlined above: reduced energy costs, increased sustainability and a healthier, more efficient working environment are all direct results of green initiatives.

Nene Warehouse Solutions are committed to sustainable development. We hold multiple SSIP accreditations (CHAS, Safe Contractor, Facilitiesline & Avetta); each independent audit allows us to review and improve our operations and further establish our environmental goals as the warehousing industry continues to evolve.

Get in touch with our expert team today to find out how we can help you reduce your carbon footprint through warehouse design, planning, and storage solutions.