Racking Protection: The Products Every Warehouse Needs.

The backbone of a successful storage facility is a safe and productive storage system. Ensuring your racking is healthy and compliant – with every pallet location optimised – gives your business and employees every chance to flourish in a secure working environment.

Yet the daily operations in any high-functioning facility present numerous risks to your racking system and your staff. None more so than collisions caused by poor or improper use of MHE (Material-Handling Equipment). Damaged or weakened components and quarantined aisles cause operational disruption and costly downtime. In extreme circumstances, cumulative damage or heavy impact may even result in potentially fatal racking collapses – so mitigating these risks with racking protection products is both a logical and responsible solution.

Despite the benefits of racking protection, it often gets overlooked. The HSE (Health & Safety Executive) guidelines recommend that racking protection is installed: wherever likely to be struck by lift trucks and other vehicles. However, a lack of legislation allows many businesses to sacrifice it in favour of additional storage capacity or view it as an unnecessary cost.

Concerning the latter: fluctuating steel prices alone provide ample incentive to protect your assets. Racking maintenance costs can quickly become unmanageable if components are left exposed. In extreme cases, failure to act can result in an unsalvageable storage system and the daunting prospect of replacing entire racks! With more than 80% of MHE impact occurring in the first 2 metres of your racking, this is an issue we can all influence with even the most basic protection products.

So, what is the most effective way of protecting your storage equipment? There are many products on the market (and not all of them serve the same purpose), so our experts have compiled a list to help you select the racking protection products appropriate to your setup, giving your warehouse the best opportunity to reach its full potential.

Steel Upright Protection

Steel protectors or Column Guards, as otherwise known, are the most common solution for safeguarding against forklift and pallet truck collisions and are a great place to start. There are multiple options on the market, with varying functions. So, which one(s) do you need for your setup?

Four-Sided Column Guard

The Four-Sided Column Guard – a standard found in most storage facilities – primarily protects the racking upright post. Typically fabricated from a single sheet of 3mm thick steel, folded into a semi-pentagonal shape and secured to the floor, they provide a robust defence against collisions without damaging your handling equipment.

End-Of-Aisle Barriers

The End-Of-Aisle Barrier provides essential protection for pallet racking. No other section of your racking is more exposed to site traffic than the first frame in the row. If left unprotected, components critical to the racking structure are open to significant impact. Again, there are multiple variations available, but we’ve outlined the two most common types below:

High-visibility Steel End-Barriers alleviate the risks at the end of aisles by providing a visual aid to forklift operators and a robust shield against impact. Available in an array of sizes to suit single and back-to-back bay configuration’s

alternative to the steel option is the Timber End-Barrier. Fixing directly into the concrete via two heavy-duty C-section columns and infilled with 100x75mm treated timber, they are

just as effective as the standard Steel End-Barrier. While any substantial impact will inevitably lead to cracked or broken timber panels, the flexibility to replace them quickly and inexpensively reduces your maintenance costs.

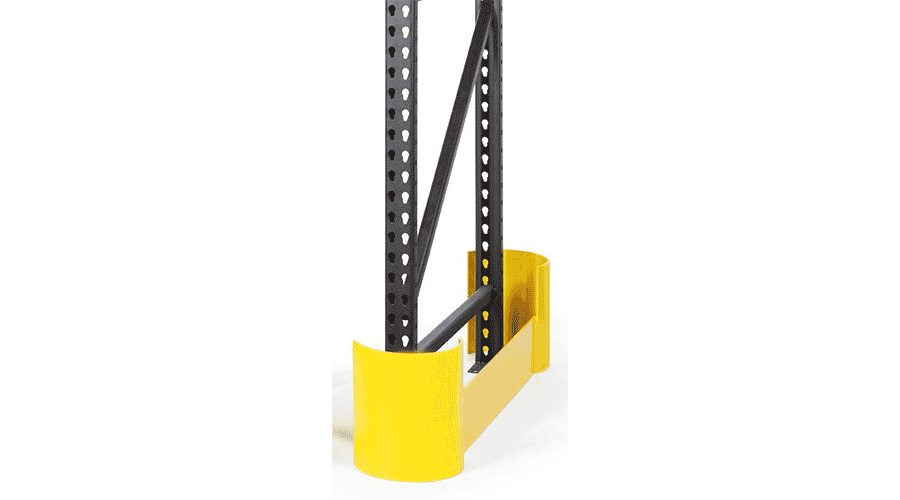

Wrap-Around Column Guard

The Wrap-Around Column Guard is a variation of the standard Column Guard. As the name suggests, it wraps around the front face of the upright, further protecting the post and the baseplate whilst protecting the low-level frame braces from the forks or carelessly placed pallets.

Corner Guard

Often, the corners at the end of racking aisles are most vulnerable in high-traffic warehouses. The Corner Guard helps to soften sharp corners while deflecting any glancing blows from turning forklift trucks. Many warehouses will use the Corner Guard in conjunction with an End-Of-Aisle Barrier for additional protection.

The Rack Deflektor

The Rack Deflektor is a low-cost, convenient, and durable buffer against day-to-day operational wear and tear and an ideal solution for high-density or narrow-aisle pallet racking configurations. Its slender design minimises aisle intrusion, protecting the most vulnerable section of your racking without a reduction in safe working clearances – allowing you to maximise your storage capacity safely.

Installing the Rack Deflektor is quick and easy: fastening to the racking upright directly with an intuitive serrated-clip system. This user-friendly lift and clip approach, combined with a durable, all-weather, high-visibility polyethene shell, makes the Rack Deflektor an ideal choice for any warehouse environment.

Tubular Guard

The Tubular Guard is commonly utilised on pallet racking profiles with a first beam level below 500mm from the floor. Beam levels below this height render regular steel guards (mentioned above) incompatible. The Tubular Guard – a heavy-duty, 500x90mm galvanised post – is fixed in front of the upright via a heavy-duty steel plate.

Guide Rails

Guide Rail systems control and maximise forklift movement while keeping your MHE operators at a safe distance from your racking. Fixing to the floor, flush to your storage equipment, they can be used in a wide range of areas within your warehouse and are particularly effective in conjunction with narrow-aisle pallet racking. Additionally, they provide an effective solution for protecting Cantilever Racking.

Warehouse Barrier Systems

A heavy-duty Warehouse Barrier System protects building columns, machinery, packing areas and loading bays within your warehouse. Additionally, they can help to fortify your pedestrian walkways by protecting your employees and clearly defining traffic lanes for your MHE operators.

Whether you’re managing a new or well-established storage facility, it is never too late to assess (and re-assess) the safety of your storage equipment; a proactive approach is essential. Signs of frequent impact or repeatedly damaged components are a helpful indicator of the necessity for racking protection. Nene Warehouse Solutions offer a wide range of products, safety accessories and services; our expert team is on hand to guide you through the process so you can make an informed decision about the future of your business.