Planning Your Ecommerce Warehouse Layout

Contents

Ecommerce is nothing new these days, but the industry is booming thanks to the pandemic and the resulting habitual changes to shopping and groceries.

There are more online channels available than ever to make purchases through, such as independent and SME eCommerce businesses on social media, as well as the supermarket giants, big brand online shops and Amazon-Esque marketplaces. So, it’s not surprising that eCommerce is expected to reach a market volume of a whopping £92,464 million by 2025 in the UK.

How does our industry handle the eCommerce boom?

The eCommerce market is established and growing, so we need to adapt to get the best out of it. While this might seem daunting, there are plenty of measures you can take to align your business with the eCommerce boom and benefit from it.

Find out more about the eCommerce boom and the effects on warehouses and logistics.

Careful planning and organisation are vital to winning in eCommerce, and at Nene, we have the knowledge, experience and expertise to get you up and running.

Things to consider before you start planning your warehouse layout

Planning is essential to set up your warehouse, eCommerce or not. But, with the demands on eCommerce customer service and expectations high, expert implementation of carefully planned workflows, equipment, and processes will make the difference.

Primarily, list out the most critical elements of the operation and prioritise them. The basics should cover how much stock and goods you intend to sell, how frequently, and what you need in your warehouse to accommodate those things – equipment, space, workers, and so on.

Understanding your requirements

Once you have the basics laid out, you can get more granular with your information and specific to your products and facilities. For example:

- What are the goods you are selling?

- Are there multiple SKUs?

- Is your stock date sensitive or perishable?

- Do they need to be protected? (e.g. Chemist items, pharmaceuticals, delicate fabrics, food items)

- Is your stock high-value? (Is extra security required?)

- Is your stock seasonal? (Do you need to change your warehouse layout throughout the year or at least have the option to?)

Deep diving into these questions from the outset will make sure you are set up to serve your customers best and be the most productive in your business from the beginning, with the correct, most efficient equipment and processes for the job.

What racking storage system is best?

Answering the questions above and collaborating with industry experts like Nene will help you determine what kind of racking system you need. Racking and storage are available for such a wide variety of goods and sizes, so you can really tailor your equipment to your exact needs.

Heavy palletised goods

If your inventory is pallet-heavy, wide aisles to use with forklifts will be ideal, as will adjustable pallet racking. You can then decide as to whether you have carton-flow for time-sensitive pallet-racked inventory or drive-in racking, for example.

Picking goods

If your pick is manual, you can consider very-narrow aisle racking, saving space and optimising storage for more products on the pick line.

Small and irregular sized goods

Storing smaller items? Then you can look at long-span shelving with partitions and mesh products, and mesh cages for security to protect high-value or hazardous products.

Consider traffic flows and pick paths

It might seem trivial, but planning the flow and pick paths in your warehouse makes a huge difference to productivity.

First, manual picking is far more comfortable for workers when they don’t have to squeeze past each other or cross paths unnecessarily. Not only that, products are less likely to be pushed off of shelves, dropped, or damaged if the pick route is efficient and makes sense.

Then there is safety – the flow of your warehouse should have fire risk and safety considered a major element – making sure manual pickers don’t have to cross paths with forklifts and cherry pickers, for example.

The workflow will be indicative of the goods to pick and the journey they go on from picking to packing and loading, using arrows, signage, one way systems and reducing bottle-necking. Mapping this out before any goods hit racking or storage is crucial – it’s a lengthy, unnecessary cost of time trying to fix it on the warehouse floor.

Nene’s warehouse design and planning services work with clients to assess every aspect of the pick, pack and load process to ensure all parties and functions are considered in the layout.

Other factors that must be planned

As just mentioned, Health and Safety should be front and centre in your planning.

Fire exits and escape routes have to be planned in by law and for the security of your employees. Your building plans will have the fire exits marked out so you can avoid putting equipment in front of them or hindering routes to them. You will need to map out escape routes as part of broader disaster and escape plans, so work these out with a health and safety officer for compliance.

Lighting is one that perhaps seems less obvious, but your pick paths and storage facilities need to be well lit, from a comfort and productivity standpoint but also safety. Areas need to be well-lit to help prevents falls, spillages, and even criminal damage. Map out your lighting configurations simultaneously with the floor configurations to ensure alignment.

Optimise pick and pack

Pick optimisation goes hand in hand with your planned pick paths and traffic flow. Measures to take can include equipment such as wire mesh decking, dividers, and crates. Nene supplies and installs high-quality wire mesh products that fit a wide range of pallet racking systems. A cost-effective way to maximise space available, mesh solutions enable you to divide stock to create a productive and timely pick.

If your inventory is seasonal, garden centre or decorative supplies, for example, you need to accommodate an influx of seasonal items on top of the BAU inventory. Wire mesh solutions are a great way to make quick changes to the workflow and get products out for delivery.

Complementary picking and packing storage systems

It doesn’t stop at wire mesh products – Nene has a range of adaptable solutions that mean you can chop and change your warehouse workflow, tailoring it to exactly what you need, when you need it:

Shelf Partitioning Systems

Robust, clip-on, customisable designs made from galvanised steel that fits any adjustable pallet racking or long-span shelving. Find out more about our Shelf Partitioning Systems.

Storeganizer

Vertically stacked, suspended, multi-row high-quality textile pockets designed to accommodate small items in easy access columns. Find out more about Storeganizer.

Pallite Pix

Nene’s range of sustainable, lightweight, flexible and robust storage and shelving systems is designed to consolidate pick faces and create more free space in your warehouse. Find out more about Pallite Pix.

Long Span Shelving

Versatile, heavy-duty long span shelving systems ideal for storing heavier products on a manual pick, making them an excellent fit for automotive parts and other hand-picked products. Find out more about long span shelving.

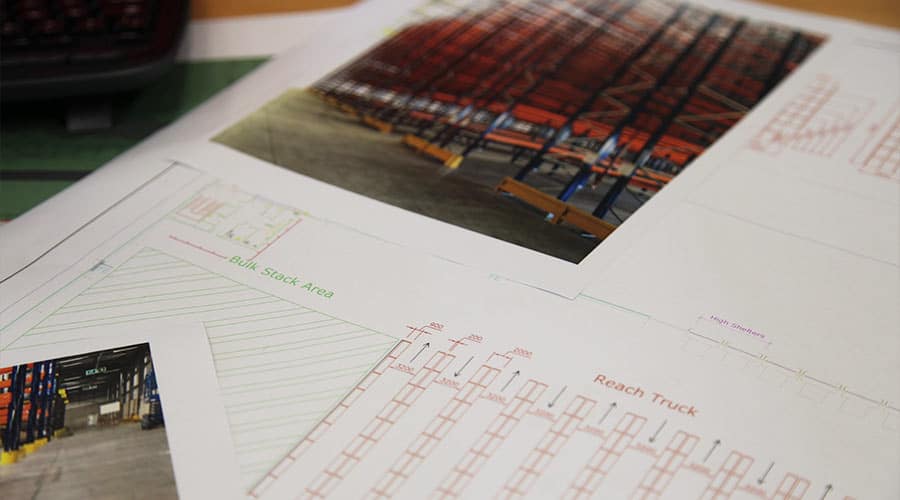

Let Nene manage your warehouse design

Nene is a market leader in warehouse supply and installation. Working with global clients for high-end brands, we improve productivity and warehouse efficiency across the UK and Europe. As a result, we can plan for your eCommerce warehouse needs, taking all aspects into account, including product output and returns and varying delivery times.

Our designers and planners can help you whether you are building new premises, relocating your facility or reconfiguring existing facilities. Working closely with you, they will carry out a comprehensive survey to define your warehousing and racking requirements – taking the time to understand your pressure points and meet your objectives.

Nene commits to making your warehousing work harder for you. Work with us, and our team will devise a comprehensive warehouse and racking design that’s cost-effective, efficient, and ultimately does precisely what you need it to.

Let Nene manage your turnkey project

Our warehouse turnkey solutions help ideas become a reality. We can manage every aspect of a complete warehouse fit out with offices spaces, mezzanines, comprehensive ranges of racking, toilets, cafeterias and more. We help some of the biggest brands and businesses in the UK, taking clients from inception to completion on high-quality, SEMA standard warehouses that are fit-for-purpose.

Led by our seasoned project managers and working closely with our design, supply and installation teams, we have the knowledge, expertise and experience to deliver your complete, fully functional and highly productive warehouse solution.

Your eCommerce warehouse needs to be finely tuned and productive to cope with customer demands. Nene can help you get there. So if you are looking to move into eCommerce or rejuvenate your existing setup, look no further than Nene to get you up and running.