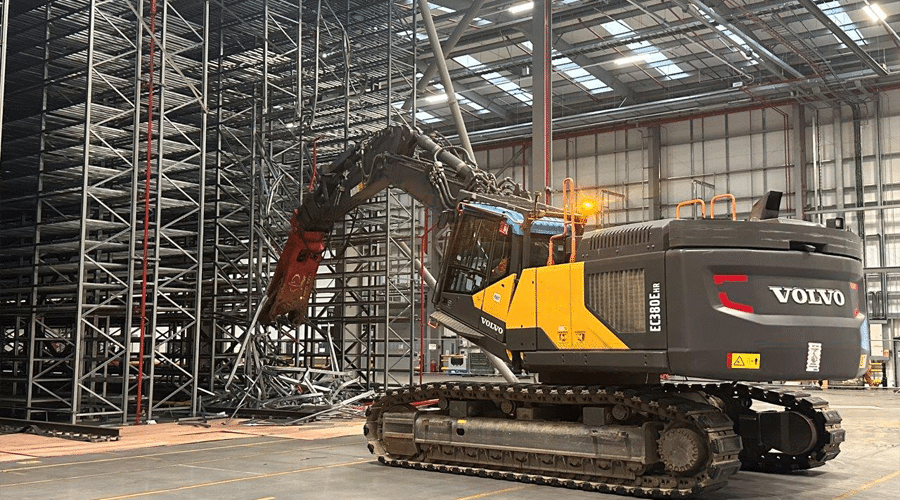

We’ve officially kicked off an exciting racking reconfiguration project for one of our long-standing clients, and it’s already off to a flying start.

At Nene Warehouse Solutions, we don’t just install and dismantle racking. We deliver projects with pinpoint precision, safety-first execution, and seamless coordination from start to finish. This large-scale demolition marks the beginning of a full transformation within the warehouse space, designed to improve efficiency and prepare the site for a completely new layout.

Every detail has been carefully planned by our expert team, ensuring the work stays on schedule while maintaining a safe, compliant environment throughout. Minimal disruption to the client’s day-to-day operations is always a key priority, and we’re proud to be delivering exactly that.

As we move from demolition into the reconfiguration phase, we’ll continue to uphold the same high standards that define every Nene project: meticulous, methodical, and made to last.

Need support with racking removal, reconfiguration or a full redesign of your warehouse space?

Our expert team is ready to help – from initial planning to final installation.

As e-commerce continues to surge, warehouse and logistics operations must evolve to match rising consumer expectations around speed, accuracy and efficiency. Despite the pace of technological advancement, it’s estimated that around 90% of warehouses still rely on traditional manual systems. That’s why more businesses are now turning to warehouse automation to futureproof their operations. From Automated Storage and Retrieval Systems (ASRS) to autonomous mobile robots, automation is reshaping how warehouses function. These technologies bring undeniable advantages, from improved safety and performance to lower overheads and higher accuracy. Below, we explore the key benefits of automation in the warehouse environment, along with two of the market-leading solutions available through Nene.

Maximising Space and Efficiency

Automated systems such as pallet shuttles and robotic picking stations streamline workflows and maximise available space. Narrower aisle requirements and vertical storage solutions enable more efficient use of every square metre. By optimising floor-to-ceiling capacity, automated systems help you reclaim valuable real estate and increase throughput without needing to expand your footprint.

Boosting Accuracy and Reducing Errors

Manual picking errors are common, especially in fast-paced or unorganised warehouses. Automation significantly improves inventory accuracy by digitally managing thousands of SKUs in real time. The result? Fewer mistakes, reduced stock loss, and more consistent order fulfilment – all contributing to a stronger return on investment.

Creating a Safer Working Environment

Warehouse automation reduces the risks associated with manual handling, working at height, and machinery operation. Unlike human operatives, automated systems don’t suffer from fatigue or misjudgement, making them more reliable in high-risk scenarios. Automated equipment also reduces internal traffic, which helps lower the chance of accidents involving manual handling equipment (MHE) and forklifts.

Driving Sustainability and Energy Efficiency

Sustainability is no longer optional. Automated solutions give you greater control over energy usage through predictive analytics and condition monitoring. Energy-efficient systems not only help reduce your carbon footprint, but also contribute to long-term cost savings. Automation is a crucial step for companies aiming to meet their ESG goals while increasing operational performance.

Stow Atlas® 2D

The Stow Atlas 2D is a self-powered pallet shuttle system, ideal for high-density storage in both semi and fully automated warehouses. It features a lightweight, energy-efficient carrier that transports pallets within a specially designed racking structure. This modular solution is adaptable to different building types and business needs. The system is scalable, allowing you to increase capacity without expanding your floor space or team.

Stow E.Scala®

The Stow E.Scala is a fully automated, goods-to-person fulfilment system. It replaces traditional lifts and conveyors with robotic vehicles that travel across storage levels via ramps. This clever design removes the need for complex, high-maintenance infrastructure. With intuitive software, on-the-fly charging, and seamless integration capabilities, E.Scala is the perfect entry point into warehouse automation – simple, efficient, and future-ready.

Is It Time to Automate?

At Nene Warehouse Solutions, we’ve spent decades leading innovation in the storage sector. Our expert team understands that the future of warehousing is built on streamlined processes, smart systems, and sustainable design. While people will always play a vital role in logistics, automation is becoming an essential investment for businesses that want to stay competitive. The technology is ready – the only question is, are you?

Speak to our team today and discover how automation could transform your warehouse.

An empty warehouse is more than just a shell. It’s a blank canvas packed with potential and an opportunity to shape operations from the ground up. For warehouse design experts, that potential is exciting. But for many business owners, starting from scratch can feel overwhelming – and rightly so.

Modern warehouse design is critical to business success and goes far beyond simply installing standard racking. It’s not just a sketch in a notebook. Effective design combines science, creativity and strategy to bring order and efficiency to even the most complex warehouse environments.

Your warehouse layout directly affects how well your business performs. When the fundamentals are sound, you create a solid base to grow from. And when you innovate, you open the door to new efficiencies, safety improvements and commercial advantage. Whether you’re fitting out new premises or upgrading your current site, investing in the right warehouse design will bring immediate, tangible benefits.

Space Optimisation

Maximising every square foot of your facility is vital, especially in today’s economic climate. A strong warehouse design uses the full surface area and vertical space by combining the right storage systems with smart layout planning. Mezzanine flooring, efficient aisle widths and product grouping all help you get the most from your space.

Improved Efficiency

A well-designed warehouse doesn’t just look good on paper. It improves your operational performance by incorporating process flow, storage equipment, product volume and material handling into one cohesive plan. Every step – from receiving to despatch – is accounted for, helping you work faster and more efficiently.

Safety

Your warehouse layout plays a major role in protecting your team. A carefully considered design provides clear traffic routes, pedestrian walkways, fire exits, compliant equipment placement and racking protection. Safety should never be an afterthought – it starts at the design stage.

Team Productivity

A well-structured warehouse makes your team’s job easier. By eliminating double-handling and confusing order-picking routes, you allow staff to move logically and confidently through the space. This boosts morale, improves output and reduces unnecessary labour.

Sustainability

Warehouse design has a direct impact on your energy usage, labour input and environmental footprint. When you design with efficiency in mind, you naturally reduce waste and emissions. From layout to lighting, sustainable decisions at the design stage lead to long-term benefits for both your business and the planet.

Warehouse Design Fundamentals

Product Type

The products you store are the starting point for any design. Their size, weight, fragility and shelf life all influence the type of storage equipment you’ll need. Knowing your proposed stock holding also helps define capacity requirements and shape your layout.

Workflow

Mapping the internal workflow is essential to ensure a seamless order fulfilment process. From inbound goods to storage, picking, packing and despatch, every stage needs to connect logically and efficiently. A strong workflow reduces delays, safety issues and operational bottlenecks.

Storage Equipment

The racking and shelving you choose will form the backbone of your facility. This must be factored in early to prevent layout issues later. Whether you need drive-in racking, pallet live systems, or standard pallet racking, your equipment should suit the product type, available space and stock rotation model.

Energy Efficiency

Environmental responsibility is now a priority across all industries. Clients and partners increasingly favour businesses that prioritise sustainability. Warehouse design plays a key part here, from installing energy-saving systems to reducing overall consumption through smarter layout planning.

Automated or Manual Solutions

Automation is no longer a futuristic concept – it’s a strategic tool that can streamline warehouse operations. Solutions like warehouse management software, autonomous robots and ASRS can bring significant gains in accuracy and output. Whether automation is right for you depends on your business model, budget and growth plans, but it should be considered at the design stage.

Speak to the Experts

Warehouse design is a complex process with long-term implications for your business. That’s why it’s worth working with a specialist who can guide you through every stage.

At Nene Warehouse Solutions, our design services are built around your specific needs. With over 45 years of experience in warehouse storage and logistics, we know what it takes to create a safe, efficient and scalable layout that works. Whether you’re building from the ground up or retrofitting your existing facility, our team is here to help – from initial concept through to implementation.

Speak to our design experts today to explore how your warehouse layout could work harder for your business.