Creating An Agile Warehouse For A Competitive Advantage

Contents

Today, warehouses and distribution centres can be optimised and mobilised within days to adapt and change based on business challenges, market shifts and different consumer buying habits. Turning your warehouse into an agile resource is key to operational success.

What is an agile warehouse?

In the traditional sense, a warehouse is used to store bulk produce and goods for commercial purposes. Over the last decade, we have seen an introduction of warehouse management systems, automation, advanced space planning and newer storage solutions that have all transformed this facility into a flexible resource for improved business operations. This newer agile warehouse setup can give businesses a competitive market edge when engineered correctly.

What does an agile setup achieve for your business operations?

A good operation has the correct, to scale, floor plan drawing of the warehouse where a warehouse layout can be reviewed and optimised at regular intervals.

Ideally, an agile warehouse setup aims to achieve the following:

- Maximise the available space

- Minimise the handling of goods

- Enables easy access to the goods

- Allows for storage flexibility

- Creates lots of working space

- It’s a safer environment for employees

At a high-level, the 6-key work areas that need a process strategy include:

- Office areas

- Receiving goods (goods in)

- Storage of goods

- Picking strategy

- Packing areas

- Shipping of goods (goods out)

How do you create an agile warehouse operation?

Creating an agile warehouse environment involves planning and having the right storage solutions for your goods. Installing and operating a flexible storage system is key in any warehouse operation.

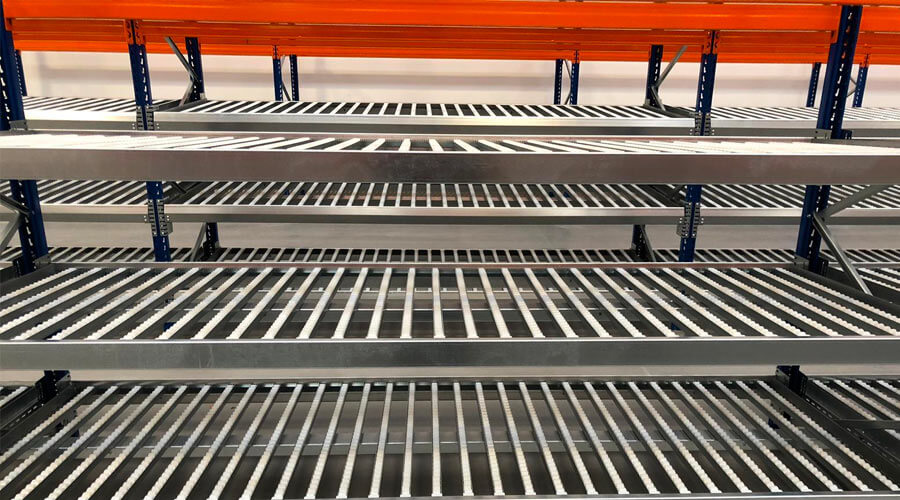

Installing the right racking

Our recommendation is to install the right racking system for your operation, and this could include rack types such as:

Other factors to consider:

Racking hire for expansion

For a shorter-term racking solution, rack hire could prove a very cost-effective way to add space to your warehouse during busy periods or for periods of business change.

Mobilisation of existing racking

It’s now possible to mobilise your existing racking and move its location to create a better warehouse flow. Using a unique technique, racking can be moved without the need for disassembly and reassembly.

Mezzanine floors

To expand office space or storage capacity, the installation of a Mezzanine floor is a great solution. This ensures you ae making full use of the fresh air above the warehouse floor.

Make use of vertical space

Where longer goods need storing, vertical racking can be installed instead of standard pallet racking bays. You can also consider Wide Aisle Pallet Racking should your goods be bulkier.

Creating an agile space is what Nene offer to all of our customers. All the points mentioned in this article are suggestions, and if you are interested in incorporating any into your warehouse setup, we would be delighted to discuss your plans and provide a no-obligation proposal.